Grease Duct Kit (Manifold Run)- Single Wall Stainless Steel Pre-Engineered Round Grease Ductwork Package. Used for the removal of smoke and grease-laden vapors. No onsite welding required

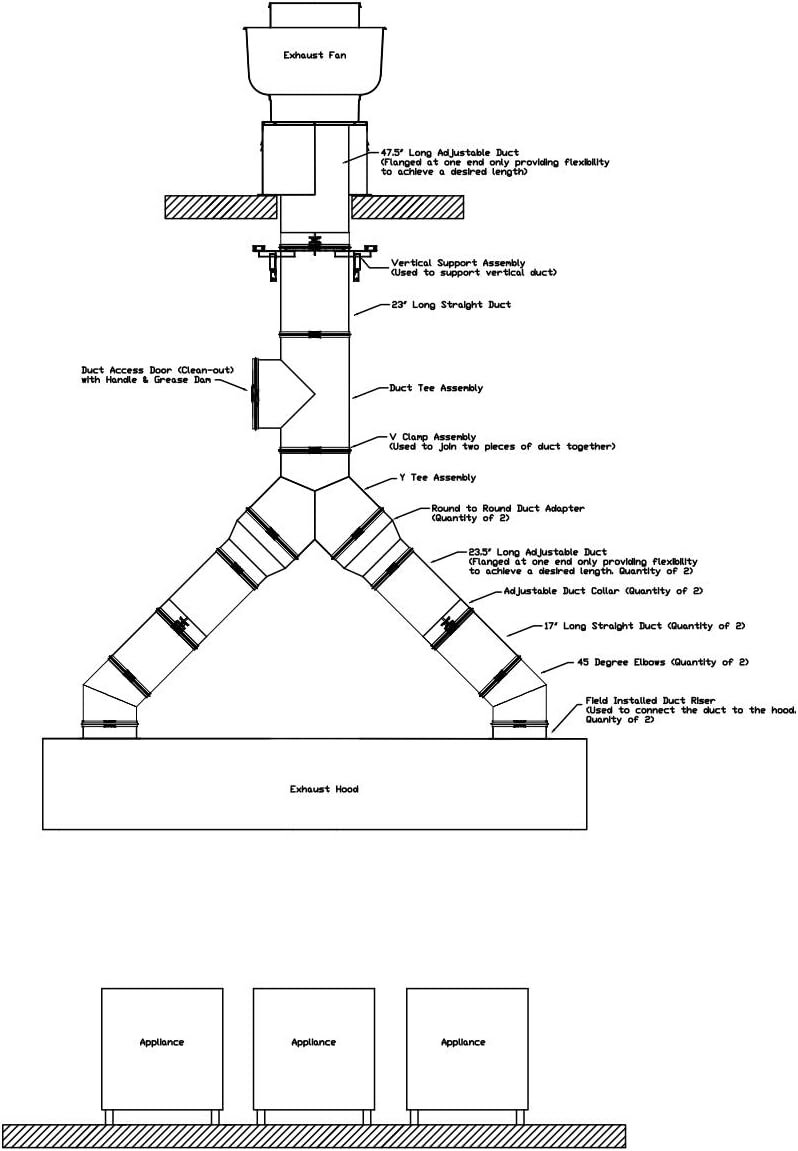

Duct package includes (2) field installed duct riser, (2) 45 degree elbows, (2) 17” long straight ducts, (2) 23.5” long adjustable duct, (2) Round to Round duct adapters, (1) Round Y tee assembly (1) 90 degree tee with access door & clean-out, (1) 23” long straight duct, (1) 47.5” long adjustable duct, (3) adjustable duct collars, (1) duct to curb transition plate, (1) vertical support assembly, (16) v clamp assemblies, (4) fire barrier duct sealant.

Perfect for duct runs that need to be manifolded together. The adjustable duct section provides flexibility for variables in the field. The duct riser and duct to curb transition plate allow for hood and fan duct connections without the need for any on-site welding.

Factory built listed grease duct makes installing and using ductwork simple and efficient. No on-site welding is required which reduces installation cost. All duct is factory tested for leaks for quality assurance. Advantages over traditional ductwork include lightweight design, easy to install, reduced labor cost, easy to clean with reduced grease build up.

Grease duct is an ETL listed, single wall construction made from 430 stainless steel. Complies with UL-1978, as well as CAN/ULC-S662. The grease duct is pre-engineered for optimum performance for exhaust fans and hoods. ideal for use in kitchen ventilation applications.

Manufactured in the USA. Twenty year limited warranty. Individual duct pieces can be ordered separately. Technical support available upon purchase. As all duct is custom built, no returns or exchanges are accepted.

Duct package includes (2) field installed duct riser, (2) 45 degree elbows, (2) 17” long straight ducts, (2) 23.5” long adjustable duct, (2) Round to Round duct adapters, (1) Round Y tee assembly (1) 90 degree tee with access door & clean-out, (1) 23” long straight duct, (1) 47.5” long adjustable duct, (3) adjustable duct collars, (1) duct to curb transition plate, (1) vertical support assembly, (16) v clamp assemblies, (4) fire barrier duct sealant.

Perfect for duct runs that need to be manifolded together. The adjustable duct section provides flexibility for variables in the field. The duct riser and duct to curb transition plate allow for hood and fan duct connections without the need for any on-site welding.

Factory built listed grease duct makes installing and using ductwork simple and efficient. No on-site welding is required which reduces installation cost. All duct is factory tested for leaks for quality assurance. Advantages over traditional ductwork include lightweight design, easy to install, reduced labor cost, easy to clean with reduced grease build up.

Grease duct is an ETL listed, single wall construction made from 430 stainless steel. Complies with UL-1978, as well as CAN/ULC-S662. The grease duct is pre-engineered for optimum performance for exhaust fans and hoods. ideal for use in kitchen ventilation applications.

Manufactured in the USA. Twenty year limited warranty. Individual duct pieces can be ordered separately. Technical support available upon purchase. As all duct is custom built, no returns or exchanges are accepted.

Duct package includes (2) field installed duct riser, (2) 45 degree elbows, (2) 17” long straight ducts, (2) 23.5” long adjustable duct, (2) Round to Round duct adapters, (1) Round Y tee assembly (1) 90 degree tee with access door & clean-out, (1) 23” long straight duct, (1) 47.5” long adjustable duct, (3) adjustable duct collars, (1) duct to curb transition plate, (1) vertical support assembly, (16) v clamp assemblies, (4) fire barrier duct sealant.

Perfect for duct runs that need to be manifolded together. The adjustable duct section provides flexibility for variables in the field. The duct riser and duct to curb transition plate allow for hood and fan duct connections without the need for any on-site welding.

Factory built listed grease duct makes installing and using ductwork simple and efficient. No on-site welding is required which reduces installation cost. All duct is factory tested for leaks for quality assurance. Advantages over traditional ductwork include lightweight design, easy to install, reduced labor cost, easy to clean with reduced grease build up.

Grease duct is an ETL listed, single wall construction made from 430 stainless steel. Complies with UL-1978, as well as CAN/ULC-S662. The grease duct is pre-engineered for optimum performance for exhaust fans and hoods. ideal for use in kitchen ventilation applications.

Manufactured in the USA. Twenty year limited warranty. Individual duct pieces can be ordered separately. Technical support available upon purchase. As all duct is custom built, no returns or exchanges are accepted.

FACTORY BUILT ROUND DUCT ADVANTAGES

Easy Installation: No welding required - simply seal and attach V-clamps

Robust Performance: Reduced static pressure and grease buildup due to round shape

Safety: Excellent fire protection due to leak testing in the factory.

Quality Construction: Stainless steel construction increases longevity and performance of the duct

Cost: Cheaper than traditional duct due to speed of installation and no welding requirement

Maintenance: No corners or edges equals less grease build up in the duct